What kind of service do you need?

YOU ARE A BUYER. ORDER READY PRODUCTS FROM JEWELRY CATALOG

Please describe the type of jewelry you are interested in, and we will propose products that we have in our collections. Some products will be ready to produce (molds ready), and some other products can be stored as 3D files which will require a few weeks to bring to life as real models with molds.

YOU ARE AN INDIVIDUAL NEEDING A UNIQUE PIECE TO BE CUSTOM MADE

You found a picture of the perfect wedding ring, or you need a custom made medallion to baptize your child, or you found a picture of a jewelry piece that you would like to modify to your taste, or to use with your own gemstone. We can help you designing and creating your own custom made jewelry piece (gold only).Since you might not be a professional jeweler, we will guide you through a simplified process to design your jewelry and calculate a price.

YOU HAVE YOUR OWN MOLDS AND CONSIDERING TO SHIFT PRODUCTION WITH US

We need to see samples of the quality of products achieved using your molds (whether this is what you want or what you don't want) to measure your expectations), see how to improve the product, see the quality of gemstones and accessories.

We still need to make a "test order" which will help to set your quality standard, using your remarks on a small test series, and this stage helps us to confirm the pricing i order to make our best offer (weights, gemstones count and carat weight, processing time, supply in materials, findings and chains according to your standards).

Prices, timeframes, QC points and quality standards are set. We are ready to take larger orders.

YOU ARE A DESIGNER OR A BRAND CREATING YOUR OWN JEWELRY LINE

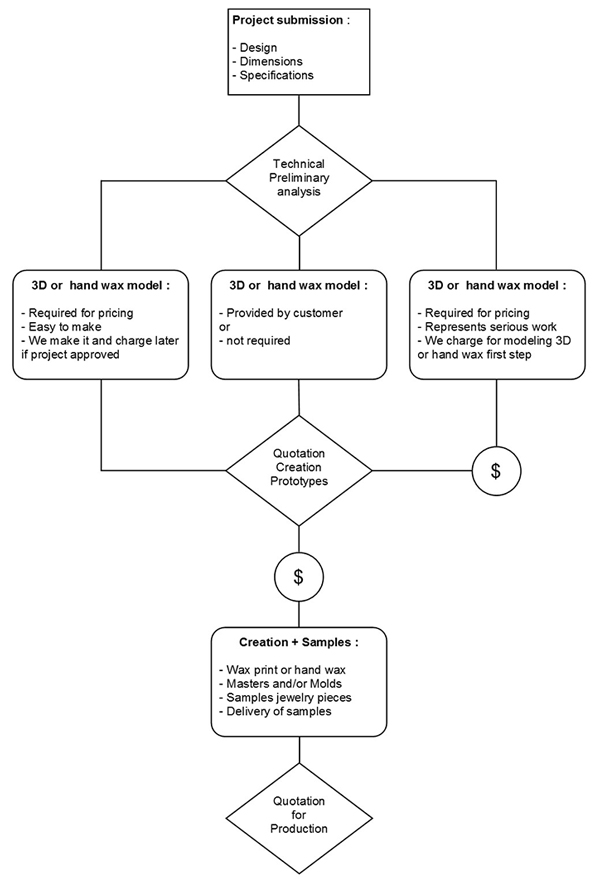

Professional jewelers, creators, jewelry designers, brands, and retailers willing to create your own line of jewelry products. The process for you is a little more detailed and a little slower as well:Prior to issue a final quotation to make molds and samples, we need:

- A cost effective design (realistic for the price point that you expect),

- Technically valid (solved mecanisms and assembly process)

- With full composition using materials that are available on the market (weights, stones count, chain set, etc).

For complex jewelry products, a simple picture or sketch or even a detailed 2D technical design will not always be enough to collect volumes and stones count to make a quotation right away.

Therefore, in such cases we will issue an approximate quotation first, and then we will need to charge for Research and 3D Design or hand modeling in order to solve issues, collect exact weights data, stones count and carat weight, as well as submitting our solutions for customer approval.

- Modeling:

Once the jewelry design is up to your need (Creation and product samples composition) we will move on to the modeling process using hand wax modeling, 3D CAD rapid prototyping or working directly on a metal master mold by hand. Sometimes we use a combination of the 3 techniques for different parts of your design.

- Engraving:

If a logo or text should be engraved by laser on a metal mold master (rather than engraving the jewelry piece by piece), we will charge for the laser engraving (and for the Illustrator vector file tracing to feed the laser engraving machine)

- Injection Molds:

From this model we create a rubber mold (metal master), a hot silicon mold (metal master) or cold silicon molds (from resins that are not castable or from any object). The 3 types of injection molds (negative imprint of an object in which to inject wax that is going to the "lost wax process" for casting) will make it possible to reproduce the pieces in series.

- Jewelry Samples:

and we deliver samples for you to confirm the product configuration, quality expectation and tolerance. After we receive your feedback we will set a temporary production price to launch a first test production with loose deadline, as we might find issues that did not apear on a few samples).

You are then ready to make your first order, called "test order", which will help:

- You to set your quality standard with your remarks on a small test series, - Us to confirm the pricing, the rejections and processing time according to your standards and confirm the supply in materials in cases were we had to find new suppliers for your specific materials.

Prices, timeframes, QC points and quality standards for finish and gemstones are set. We are ready to take orders in larger quantities with optimized prices and timeframes.

CREATION AND PROTOTYPES COSTS

Quotation for CREATION and SAMPLES.CREATION:

Creation is to be paid only 1 time per product version, (with additional tasks charged later as required for additional sizes or structural modifications of a product). .

Modifications or variations as well as additional sizes can generate more expenses, but we always notify and charge the customer before engaging in additional expenses.

To solve and design the product in compliance with the matérials available on the market, and make it technically functional, while optimizing the weight or finding solutions to reach the price target.As explained before (Submission with 3D Editable files) we migh still charge for minor 3D adjustments and compensations even if the jewelry 3D design files are provided..

Using hand wax modeling or rapid prototyping to print a wax from a 3D Design file, this step is the first materialization of the product that can be used to make a physical mold.

Moslty 3 types or printing materials:

- Wax printed by unidirectional CNC machine

(cheap, for simple flat objets, or simple rings), - Non-catable Resins printed by RP machine

(a bit more costly, for complex objets, we must use cold silicon mold only, no laser engraving of logo is possible unless we make intermediary cold mold and metal master casting, only big logo or big text from 3D file can be nicely rendered, and it will not be very sharp) - Castable resin printed by RP machines

(To be used for complex objects when we need to do laser engraving of small and/or sharp logos and text, or when we need to be very precise i the resolution of details, or when some additional work must be done on a metal master mold to assemble parts, make hinge or systems. This is th most costly printing method, but with high precision between design and real objet because of low and predictable shrinkage as well as high resolution of details on the jewelry)

The master (positive mold master) is the piece used to make the negative injection mold (rubber or hot silicon or cold silicon).

- A master can be also made directly by hand in the metal.

- It can be obtained from casting a CNC printed wax (from 3D) in silver or brass.

- The wax itself can be the master if we use it to make a cold silicon mold.

- The RP printed resins are often used as Masters when they cannot be casted (uncastable resins)

Or they are used as "Grand-father" from which we make a mold, cast a master, on which we can engrave

But then it is often more economical and more precise to just print a more expensive resin (castable one) unless the jewelry piece is large. .

PLease have a look at the Portfolio Gallery / Creation section

(Deep Laser Engraving on Master to imprint clear image on the mold)

- Some patterns, logos and branding can be printed in the 3D design, then printed (minumum line thickness 0.3 mm)

- Smaller Logo or text must be engraved by laser in the metal master mold, before making the injection mold so the patterns or text can be already on each piece after casting.

- Smallest text and logos might be possible to engrave only piece by piece

Please read the engraving section to see the limits for engraving in the mold or engraving piece by piece.

- Cold silicon mold, transparent, is made directly from a non-castable resin, a wax or any other solid material that cannot be heated (800 THB small ring - 1000 THB large ring -1500 THB Bangle).

- Hot Silicon Molds, for detailed textured surface or fine text engraving (cheaper 600 THB small ring - 800 THB large ring -1200 THB Bangle)

.

- Rubber molds, for large pieces with no perticular surface details (cheaper 400 THB small ring - 600 THB large ring - 800 THB Bangle)

SAMPLE PRICE in quotations (prototype):

We do not sell samples/prototypes at quoted wholesale price for production (factory price).

Given the amount of time spent in adjustments, briefing our workers, reporting to customers, and the unnecessary stock generated in materials and stones from our suppliers (wholesalers), we cannot sell samples/prototypes at wholesale price. So we give an indication of what the production price will be, but we charge the jewelry samples at a higher rate (silver samples +100%, gold samples +25%).

SILVER :

We show separatelly our costs for:

- Silver rate and weight,

- Metal wastage

- - on table: 8 to 10% casting/filing/polishing included

- - pave setting: additional 2% to 4% for pave - Finding and chains

- - Wastage on chain 3% pendents with sizing ladderto 5% complex necklaces (cutting/recycling)

- - Cost for jumprings is including the welding, average 8-10 THB/pc - Stones count, carat weight and rate per carat nad/or per pc, at cost.

- Labor

- - wax injection @3THB/gram, minimum 5THB

- - wax cleaning (pcs per man per day@1500THB to 2000THB based on skill required for product)

- - casting (pcs per tree @700THB)

- - filing, for each part, (pcs per man per day@1500THB to 2000THB based on skill required for product)

- - polihing (pcs per man per day@1500THB to 2000THB based on skill required for product) - Electroplating at cost, certified thickness by x-ray test +/-20% in micron for gold plating only.

We apply our profit 25% of selling price on silver jewelry (meaning the margin on costs is +33% on silver).

Total Selling price (Unit Price) for medium production as indication

* Silver samples are sold +100% with minimum usually 2pcs , up to 5 pcs

Example: A small ring, 4 grams (4 x 20THB/gram x1.1 = 88THB), wax injection (4x3 = 12THB), casting is 40pcs per tree (700/40=17.5 THB), filing 70pcs per man per days (1500/70= 21.4HB), polishing is pcs per man per day (1500/140= 10.7THB), take the subtotal x1.33 THB = 199THB per ring.

* The labor rate @1500THB per man per day will go down depending on turn over and volumes, and for regular custmers.

GOLD :

We show separatelly our costs for:

- - on table: 8% casting/filing/polishing included

- - pave setting: additional 2% to 4% for pave

- - Wastage on chain 3% pendents with sizing ladder to 5% complex necklaces (cutting/recycling)

- - wax injection @3 THB/gram, minimum 5 THB

- - wax cleaning (pcs per man per day) conversion for same product in silver = x3 for 18K, x2 for 9k 10k and 14K

- - casting (pcs per tree @1,100 THB)

- - filing, for each part, (pcs per man per day) conversion for same product in silver = x3 for 18K, x2 for 9k 10k and 14K

- - polihing (pcs per man per day) conversion for same product in silver = x3 for 18K, x2 for 9k 10k and 14K

We apply our profit 17% of selling price on silver jewelry (meaning the margin on costs is +20% in gold).

Total Selling price (Unit Price) for medium production as indication

* Gold samples or unique pieces are sold +25% of wholesale price with minimum usually 1pcs , up to 2 pcs

Example: The same ring model as silver example,but inyellow gold 18K:

A small ring, 6.3 grams (6.3 x 1200 THB/gram x1.08 = 8,164 THB), wax injection (4x3 = 12 THB), casting is 40pcs per tree (700/40x3=52.5 THB), filing 70pcs per man per days (1500/70x3= 64.2 THB), polishing is 140pcs per man per day (1500/140x3= 32THB), take the subtotal x1.2 THB = 9,990 THB per ring.

* The labor rate @1500THBx3 per man per day will go down depending on turn over and volumes, and for regular custmers.

* Diamonds below 0.1 ct - 0.3ct - 0.5 ct supplied by customer will be marked up only 5% - 3% - 2% for liability/consignment, larger diamonds only 1%.

This pricing is discounted for large orders and surcharged for very small orders.

And of course it is modified:adjusted on case by case basis to fit a given customer business model (bulk orders, websites repeated small orders with semi-finished products stock, etc)

As explained before, in some cases the detailed quotation is given only after payment for Research and 3D Design (or wax modeling) for complex design or designs that are not well defined or lacking of information such as the exact stones count, the weight, or a structure that makes the weight very hard to guess, etc.

- Estimated weight, labor, plating costs updated after samples are made:

- The metal weights, gemstones weights, chains, findings and plating costs are estimated from the provided 2D technical design, the jewelry 3D design, or the jewelry wax modeling by hand that was charged in earlier step, and such data will be adjusted after we create the jewelry samples.

Usually the metal and stones rates remain the same and we only adjust the real stones count and exact metal weights.

- Minimum Order Quantity (M.O.Q.) for Samples:

Depending on the design, the stones, chains or other materials we might impose minimum quantities for samples.

- SILVER: generally 2 to 5 pieces minimum for silver samples.

- GOLD: The rates are higher so we try to not impose any minimum (1 piece is fine unless stones or chains cannot be sold in such small amount)

- Specialized Tasks:

Some elements in the pricing cannot be quoted before a piece of the product is made.

Ex:

- Plating cost for large chains or complexe products (our technician need a plain piece in hand to evaluake the surface using direct plating or dipping techniques)

- A products made by casting before preparing stamping dice for mass production by stamping method.

- Gold-filled jewelry samples,

- Iinlays and fancy cut stones cut-to-fit the molds, and other materials needing samples before obtaining a price from subcontractors for specialized tasks.

DIRECT Jewelry QUOTATION // OR RESEARCH & DESIGN FIRST

If the jewlery design involves simple geometric shapes we can estimate weights easily as long as we have global dimensions.

It is preferable to have a detailed 2D Technical Design in order to make accurate price estimates for the jewelry.

Technical design means that no dimension is left unspecifed, and that it is "working", with hinges and systems already solved.

Sometimes even a tehcnical design will leave us with difficult volumes and gemstones count to calculate or will require design and structure solving.

In such cases we will charge as first step a study and design 3D (or wax carving by hand) prior to make pricing.

QUOTATION TIMEFRAME: Before sending any pricing or commiting to the creation of a product we must make sure that our interpretation of the design specifications is correct in matter of dimensions, proportions, gemstones sizes and fitting, technical details of parts and assembly.

We must also verify availability of gems and materials on the market, in the required sizes, or we must propose alternatives.

Pricing means solved process and supply, it can take 1 or 2 days or a week in some cases.

Design/Creation is part of pricing optimization : No modeling = not much negociation possible.

Design is a step during which we will operate major choices and optimizations that can impact the price of the jewelry up to 30% up or down: Weight and thickness, amount of parts to be assembled, size, and spacing of gemstones, findings, etc. Discussing or negotiating FOR BEST PRICE before this work is done is not very constructive unless the design is very simple.

Nevertheless we will consider suggestions aiming at simplifying the design or using cheaper materials in order to bring the price down.

I PAID FOR 3D DESIGN, THEN I RECEIVED A MORe PRECISE QUOTATION :

What if the pricing does not work for ME?

How to walk away before the end of the jewelry creation process? What do I get?1) Reserch and Design Only (Payable up-front):

In some cases we will need to charge for Solving and Design before being able to make a precise quotation for making the model, mold and samples.

If you are happy with the result, but rest of the Creation process (printing, modeling, molds) is too expensive, or if our projections and estimates for the final productoin price are too far from your target you can either:

- Stop right there, you have 3D multiple views with dimensions, STL File, and solutions and detailed quotation (labor costs, detailed materials list and rates).

- Pay the Exit Fee (same amount that you paid to initiate the work) to retrieve the editable 3D files, meaning 3DM files on top of the STL files which are printable but not editable

- Go to next step and see if the price is getting better once the samples have been made, because you trust us with the quality of the creation even if you might not take our prices for production.

2) Modeling, Masters, Molds and Samples (Payable up-front):

We generally always make samples when we charge of modeling/printing resin and molds for a new model, because it is the proof that our tooling is working.

We deliver samples, then you can do the following:

- Stop right there, you have 3D multiple views with dimensions, STL File, and samples as well as detailed quotation (labor costs, detailed materials list and rates). You can still use the non editable 3D File (STL) to make the same tooling and molds again with another manufacturer.

- Pay the Exit Fee (same amount you paid up to this stage), to retrieve the editable 3D files (if any) and the injection molds (rubber or silicon molds) allowing you to continue the production elsewhere.

- The production price is not far from your target price, you can place a first "test order" to optimize price and timeframes.

*** Very Detailed Quotations:

When our prices are a little too far from your target, we generally propose options to bring the price down (remove stones or space them, simplify a chain set, reduce some dimensions or thicknesses that are responsible for heavy product, reduce the plating, etc). Our quotations are very detailed, showing metal weight and rates, wastages, stones counts, and all market prices separated from our markup.

*** Intellectual Property:

Your design, files and tooling remain protected by our standard NDA contract wether you retrieve your tooling or not.

We will keep the tooling in stock for at least 1 year after our last communication in case you change your mind.

*** Keepig your tooling available:

In most cases we can produce extra injection molds for you on demand, even if you produce elsewhere.

(Payment terms for creation and samples)

HOW TO SUBMIT A JEWELRY DESIGN FOR A QUOTATION REQUEST

|

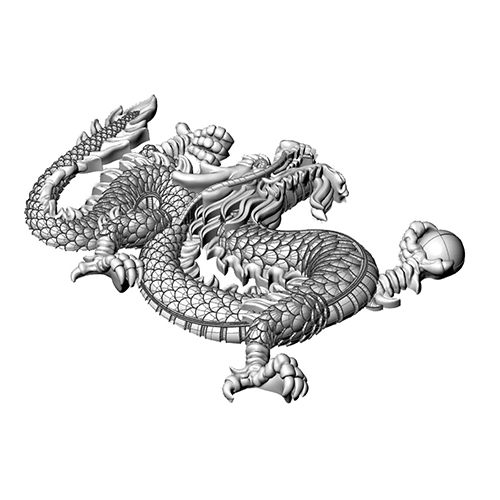

| Figure on the left: A customer will send us a picture and ask to have this dragon made as a raised 3D dragon. The impact of the dragon on the weight of the jewelry is not negligible, and we do not know how much gold can be saved at the back of the dragon unless we actually make the design. So we an approximate pricing only, and we charge the customer for the design only as a first step. We decided right away to make the scales on the skin of the dragon to be larger than the initial drawing in respect for the maximum resolution of the Solid Scape wax printing machine.. |

The best way to receive a fast and precise quotation. Depending on the simplicity of the design we might still need to make a 3D Design work prior to deliver a quotation.For very simple designs we can make the price direclty or we might take the risk of doing a 3D design preview (not perfect) right away to get a more precise quotation very fast (charged only if you go ahead with the project).

If we are provided the jewelry 3D design file we should be able to provide a precise quotation. In this quotation we might still charge a small fee for research, inspection or modification of the 3D file regarding the technical viability and the compensations for general shrinkage:

- A global percentage (3%, 4%, 5%) for casting a master and/or making the molds and thencasting again the final product) and for surface .

- In some cases a surface compensation (+0.15 to 0.2mm on each surface) to compensate filing (sandpaper cleaning after casting) and polishing.

When the design is submitted on a 2 dimensional sketch, or as a single view picture, we will appreciate notes to be made on the drawing itself, rather than long text of explanations on the email. Please try to provide as many details as possible to help us imagine the 3D configuration, relief, raised and recessed areas as well as hidden areas,etc.

The research and jewelry design step might be charged prior to give a pricing.

In such cases the Research Fee might be slightly higher than a similar project presented more professionally.

Ex : The worst design submission is a picture copied from internet and sent to us via mobile phone with absence of dimensions, weight or composition details.

As always we bring our full insight and suggestions regarding technical solutions, cost optimization, choice of stones and materials, but the more we need to bring to the table the more the "Research fee" will be high for projects requiring a lot of support and solutions from us.

* We decline any responsibility concerning copyrighted designs and patented designs. The customer must take his responsibility when asking us to create jewelry. If the copying behavior of propriatory designs is too obvious we might refuse the project or ask the relation between the customer and the original designer. We accept and respect the concept of "inpiration", but not that of plain "copy" uless the design is a classic.

The Jewelry Design stage purpose is to make the creation possible, bring technical solutions and a cost effective interpretation using available materials. Therefore in case we charged for Research, 3D Design or hand, Wax modeling and we find technical restrictions that will not allow the exact configuration whished by our customer, then we are not bound to respect precisely the customer specifications provided before the design stage. We allow ourselves to bring slight modification to make the creation and the production possible, and of course participation, ideas and solutions brought by our customer are welcome.

Nevertheless if no realistic solution is provided by the customer we will deliver our version of the product and will not make any refund for claims arising from the fact that the concept was not realistic "as dreamed" with the technology or materials at our disposal in a conventionally equiped jewelry workshop.

JEWELRY CREATION PROCESS and TIMELINE

During the construction of the jewelry prototypes you will receive pictures at each stage of the production and you will have opportunities to give your opinion, modify and participates to resolve technical or supply restrictions, optimize the costs, etc. When you receive your samples you already known pretty much what is in the package because you have seen the evolution of the product from 3D, to the finished piece.

In case some modifications whished by the customer will require extra molds, extra printings or redesign, these cost will be proposed and explained before we operate the modifications.

This is the longest and most difficult stage of development.

Typically it will take between 4 and 8 weeks between the moment we agree on the Design to be created the first Prototypes to be delivered, and can be up to 12 weeks for a large collection to be ready for the market depending on:

- Design Complexity

- Amount of products, and variations of each product

- Materials (standard or additional sourcing time to find specific materials)

- Modifications during the Creation process

- Adjustments, redoing, fitting

JEWELRY CREATION PROCESS TIMELINE

|

PROJECT SUBMISSION: 1 to 3 days - First Contact, Submission, Questions, Research, eventual pre-design. DESIGN STAGE: 1 to 5 days - A small group of simple items or 1 more complex item QUOTATION: 1 to 5 days - For solutioning, sourcing materials, Pricing - Payment of the CREATION STAGE The below Timeline is including many materials and processes that are optional (enamel, inlays, stones, chains). Of course the more the product is simple the more you save weeks of process. A couple of products, quite simple, can be covered in 3 to 4 week. CREATION WEEK 1 : - Prepare Files for printing, place supports to avoid incomplete printing - Wait other designs from other customers to print a full tray - Print wax, or make wax by hand - Eventual redoing CREATION WEEK 2 : - Direct Mold from Wax, or Casting of a Silver Master - Adjustments and calibration of the master - Solving Technical Difficulties can send us back to Design/Printing in week1 CREATION WEEK 3 : - Eventual Illustrator design + laser engraving of logos on masters - Make a mold from Silver Master - Test Injection waxes - Eventual adjustments on Master + new correct Molds CREATION WEEK 4 : - Casting - Cleaning, pre-polish. - Assembling (chains jobs) CREATION WEEK 5 : - Assembling (chains jobs) - Setting - Other materials like Wood or stones inlays cut to fit each piece - Plating (End of creation for simple products with stones) CREATION WEEK 6 : - Plating - Enamel, gluing Wood or stones inlays - QC, Solve Surface imperfections - More structural imperfections can send us back to casting in week4 CREATION WEEK 7 : CREATION WEEK 8 : - Eventual redoing as explained in other weeks will bring us here... - Eventual Sourcing problems to find the required stones, fndings or chains. - Eventual Queuing in Development or production rush (Productions have priority on Creation) In case of large collection be ready for another 4 week until every last item is ready and approved by the customer. This depends on the period of the year and high seasons (see our Working Days Calendar). |

IMPORTANT RESERVES:

During the production of the prototypes the customer will have opportunities to adjust the product.

Very often customers will realize they need to make important changes.

- A misunderstanding is not considered as a fault from our side, even if we received Technical Designs for interpretation and modeling reference (only bad quality of execution is eligible for free redoing/changes).

- Adjustments are part of the investment to be made around the product development which can be but is not required to be prefect at first attempt. The more the product is complex the more the customer should prepare to have a second optimized version of samples to made before the product can be put on the market.

- If the designs 3D are provided by the customer asking us to work from there instead of paying us for rebuilding the product ourselves, then we will not be responsible for printings issues even if we reviewed the design on 3D before printing. We cannot find all imperfections from viewing and measuring a 3D Object, the safest way is to build it from the beginning to our standards (thickness, pave spacing, etc.).

- During the Modeling stage, if the Design is not technically functional (realistic) and if no valid solution is proposed by the customer we reserve ourselves the right to choose the best available solution to render a result as clause as possible to the original idea/concept.

FRIENDLY ADVICES:

-

Never promise anything to your customers before you have a satisfactory sample in hand.

We know that you need to plan, but going too much ahead of the real stage of the project is a risk. We will not be responsible for promises made for a product that does not really exists yet.

Make sure to keep 8 to 10 weeks between the START OF CREATION of a few product order ANd YOUR NEXT SHOW, and better plan 4 months in advance for a large collection.

- Avoid major changes of the concept or design during the creation stage, unless you are ready for eventually more expenses and delays.

Eventual changes in the design are possible, but it requires to redo some tasks that we already passed (Ex: Wax is printed already, so we need to change the 3D Design and reprint), then we will charge for redoing these steps again, unless the problem was about the quality of execution of the work.

Changes will impact the Timeframe previsions.

- Name your products and pictures, use such product codes to refer to them in your emails. Illustrate your explanations with sketches, a picture with short notes and dimensions on it worth more than a long explanation.

Take the risk and draw something with dimensions and notes. We promise that we will not to make fun of you and we will be grateful for the effort you made.

- We work from distance and creation is a slow process.

You will be subject to long periods of being idle and waiting for the results to come. Creation and preparation of a line of jewelry product, and establishment of customer standards is a slow process especially at the beginning of a relationship. It can generate some stress and unsecured feelings.

That is why starting small is always the best solution in order to build trust and to learn how to work together.

Try to not develop more than 5 complex products to 10 simple products at a time with us at the beginning of a relationship.

Thank you.

PRODUCTION IN SERIES

The customer received the prototypes samples and a few days later we will send the production prices according to real data.

We collect eventual remarks and if necessary we quote for adjustments to be made, new molds and samples.

If everything is perfect then we will be ready to make a Test Production run.

We do not set M.O.Q to give their chances to newborn creators and brands, as well as retailers websites.

This is unless it is using certain materials such as:

Small gemstones for pave setting (0.5 carat per each stone/shape/size/color minimum),

Chains: (common silver chains do not have minimums, common gold chain are 10g minimum, others 75g or 150g minimum),

Other materials where suppliers will impose minimums to us, like specific rare findings, gemstones cut-to-order, mother of pearl carvings, etc.

So there is No M.O.Q, instead we do have a LAUNCH FEE + UNIQUE PRICE

Instead we apply a Launching/Logistics/Handling Fee PER IDENTICAL PRODUCTS.

It is 300 THB (10 USD) per technique or type of materials used in t his style.

[CASTING][LASER][PLATING][ENAMEL]

[CHAIN][FINDING]

[DIAMOND][PRECIOUS][SEMI-P][SYNTH][PEARL]

[OTHER]

EX: A ring, plated gold with semi-precious stones would be:

[CASTING][SEMI-P][PLATING] = 900 THB / 27 USD

To launch the order, no matter if you order 1 pc or 500pc.

Still the same amount for launching the order.

PRODUCTION IN SERIES : CAPACITY

(deposit 70%, or 40% +30% after last parcel delivered of an ongoing previous order)

Small and medium Jewelry Productions, on demand, will generally have a timeframe of about 20-40 working days.

In this case we cannot guaranty that the orders can start immediately when you decide to place an order.

We set the starting date and timeframe depending on the products complexity, the quantities and the workload at the time when the customer decides to submit his order list to place an order.(Working Days Calendar, and high season periods). The timeframe might also be influenced by the materials sourcing timeframes from our suppliers (stones, finding and chains).

As a matter of fact we cannot plan or predict the needs of customers i

n advance and we cannot finance a stock for customer's protected products because we are not allowed to sell them to anyone else.

*** A solution is to stock half finished products with us (castings and rough filing only), so we an do polishing, setting and plating when you need the products. This is a good solution for responsive production for websites offering may combinations of stones (and plating colors for silver jewlery).

We cannot be ready at all time to produce suddenly a large quantity for everyone (customer design/products that we cannot sell ourselves).

Priority goes to the ones who plan in advance, especially for high season like September to November to prepare Christmas

Therefore, larger productions that are not planned in advance, will require 5 to 10 working days of preparation before the production can start in order to source materials, clear tables and allocate manpower, depending on the products complexity, the quantities and the workload at the workshop at the time the customer decides to place an order.

The Timeframe will be from 30 to 60 working days. We can arrange multiple deliveries and payments every 2-3 weeks starting from the 4th-6th week in order to accelerate replacing rejected goods, QC, and to allow the customer to start his own sales or deliveries.

.

The more our customer can commit to minimum quantities for each product on a certain period, the more we can commit to deliver (3 time more than customer commit to order).

We can guaranty a certain production capacity in exchange for a guaranty of orders from the customer, in the form of a manufacturing plan established for a 180 days period or more.

- The customer would ensure the production of a certain quantity for each item (different for each item) in his collection, over a minimum of 4 periods of 45 days.

- We will guaranty the production of up to 3 times the quantities for each product if needed.

- The quantities do not need to be large, only the commitment is important.

This commitment allows us to allocate a part of our manpower to a given customer's project with respect for other customers' accounts and with respect for our workers' job stability.

EX:

If the customer commit on minimum 100 of a given product pieces every 45 days during a 6 months period then we can deliver up to 300 pieces every 45 days if suddenly needed.

Benefits of a Manufacturing agreement :

- Guaranty of capacity

-

Fast start upon request for additional quantities.

- Fast turn-over with quality (manpower allocated, knowledge of the product by workers, materials stock)

- Better after-sales services like returns, rejections, repairs (continuous deliveries)

- Virtually no limit to the production capacity since the customer is building his own production unit progressively we can hire more workers specifically for the account.

There we can deliver generally within 20 to 30 working days in larger quantities.

*** We have not renewed stock since 2019

*** No catalog available, please ask with reference pictures for similar products

Website Major Conditions Updates:

Last Update (No more Discount per product quantity nor surcharges for Low Quantity,Fix Unique Price, Introducing Launch/Logistic/Handling FEE to start order for each product. 2nd FEB 2022)

Last Update (Introduce Discount per product quantity, Jewelry photographer partnership, simplification for redundant text on index page, Jan 2020)

Last Update (no major changes in conditions, text corrections, 16-Nov-2018)

Last Update (no major changes in conditions, June-2017, calendar, friendly advice)

Last Update (New Discount System, global orders, no deadlines on Creation rule, June-2015)

Last Update (Entry-Exit Fee System starting, 2014)

Last Update (Large collections Silver and Gold, complex jewelry, big lessons, Creation Fee first change 2013)

Last Update 2011 (Operating from Thailand only, Jewelry production starting, gold unique pieces mostly)

Website Creation 2007 (Design/modeling Service only operating through sister company in USA as payment/liability gateway)

Company Manja-Thai Co., Ltd since 2006